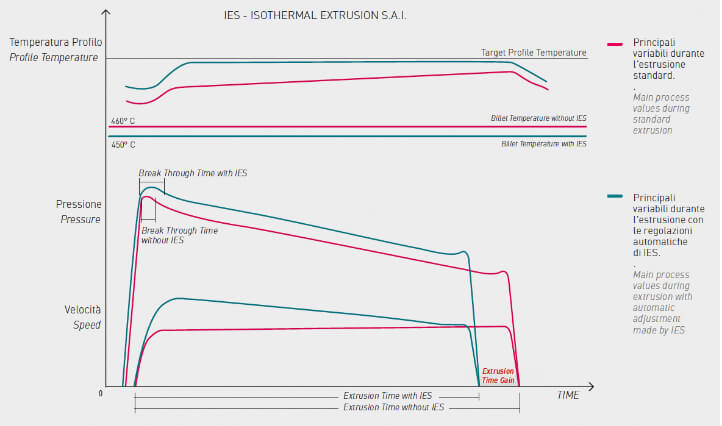

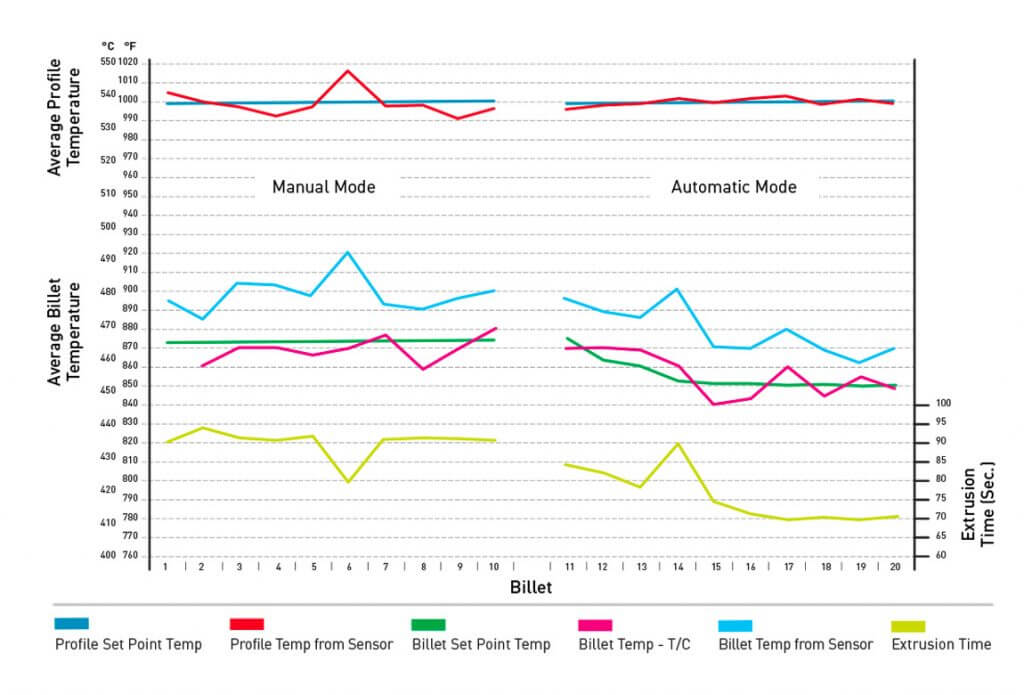

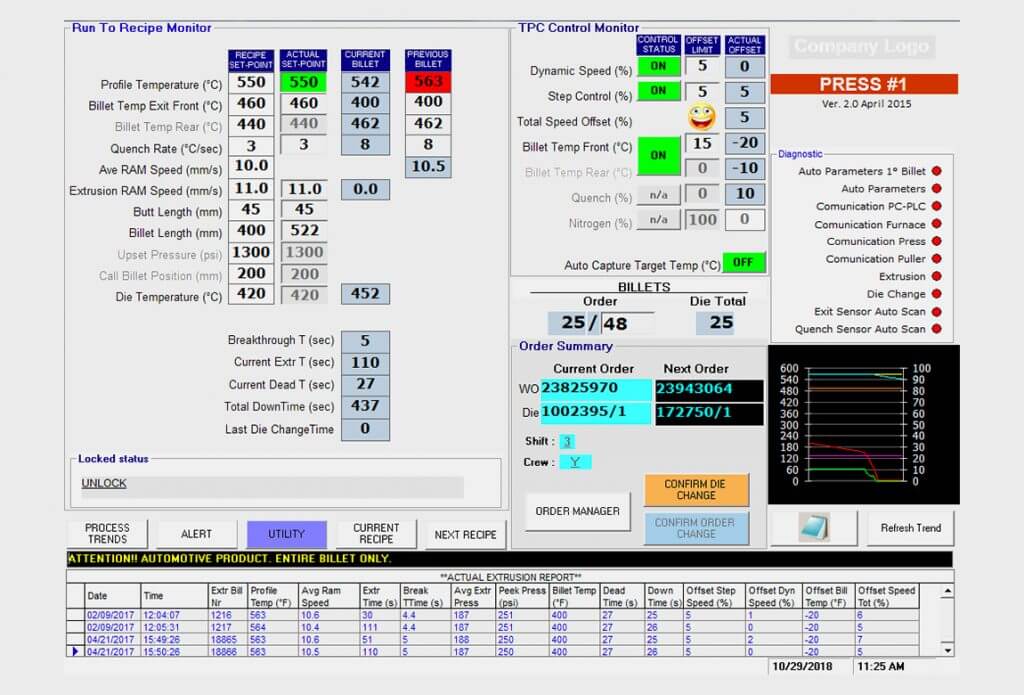

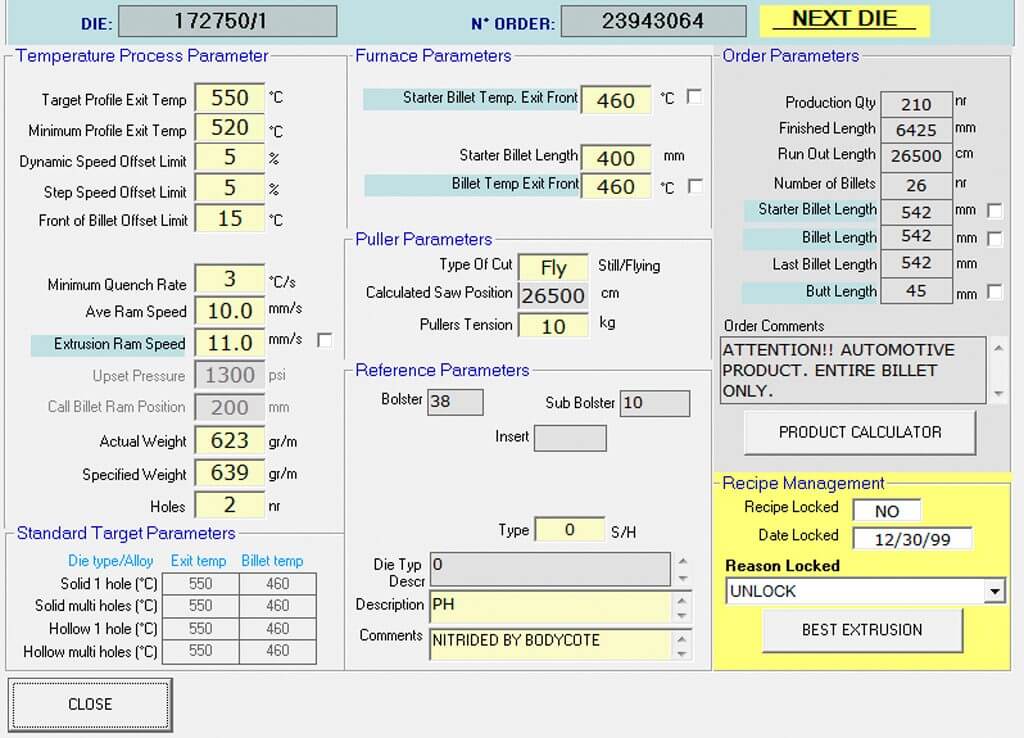

The use of IES and IES PLUS enables the achievement and maintenance of constant product quality by managing billet set point temperature outbound from the kiln and press extrusion speed, resulting in a considerable increase in production and the reduction of waste.

Main advantages

- Constant profile temperature (Isothermal extrusion)

- Automatic optimization of Peak Pressure and Break Through Time

- Increase of Extrusion Speed

- Reduction of Extrusion Time

- Lower extrusion temperature of the billet

IES and IES PLUS can be integrated with every plant, thanks to the ease installation and simple usage, without press stop.

IES and IES PLUS interface seamlessly with the customer’s existing equipment helping to maximize the production rate and quality levels by using the best press features.

MAXIMIZE BREAKTHROUGH, QUALITY, & PROFITABILITY

- Increase Press Speed 10-20%.

- Improve product quality with better surface finish, fewer defects, and reduced scrap.

- More consistent press performance with each operator running to Best Practices Standards.

CLOSED LOOP CONTROL

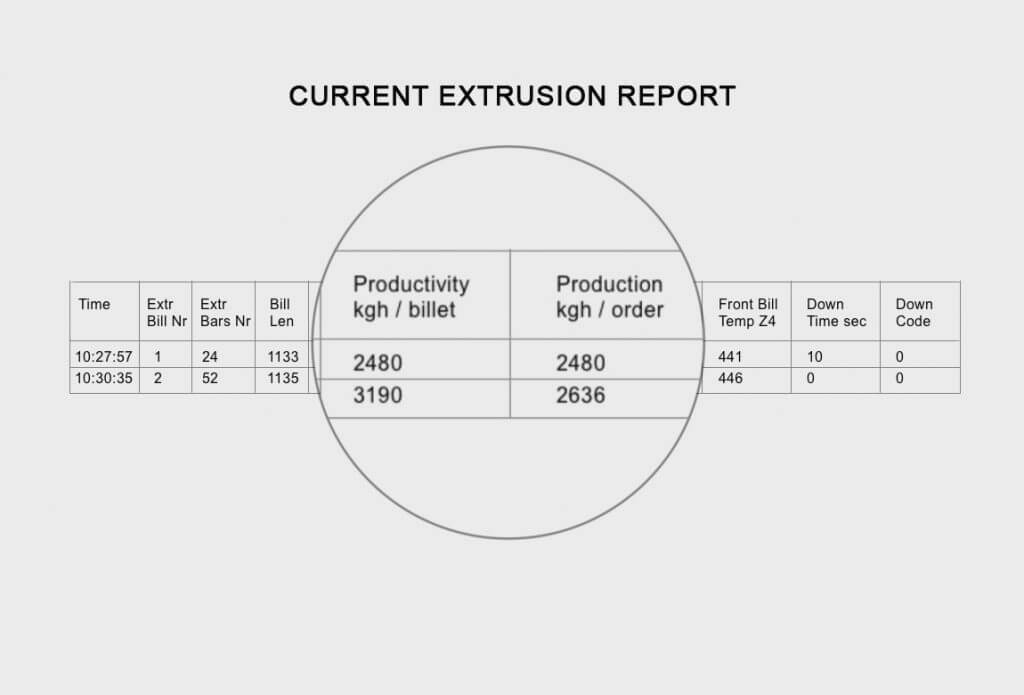

Automatically optimizes billet feed temperatures and profile temperatures at the exit of the press to increase speeds and assure high quality.

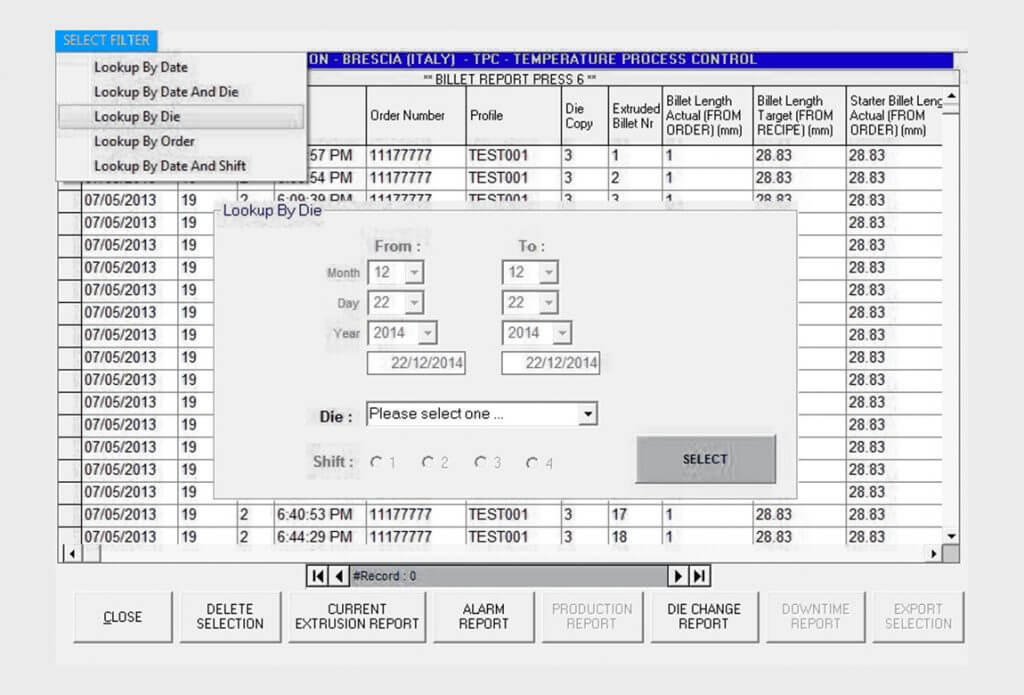

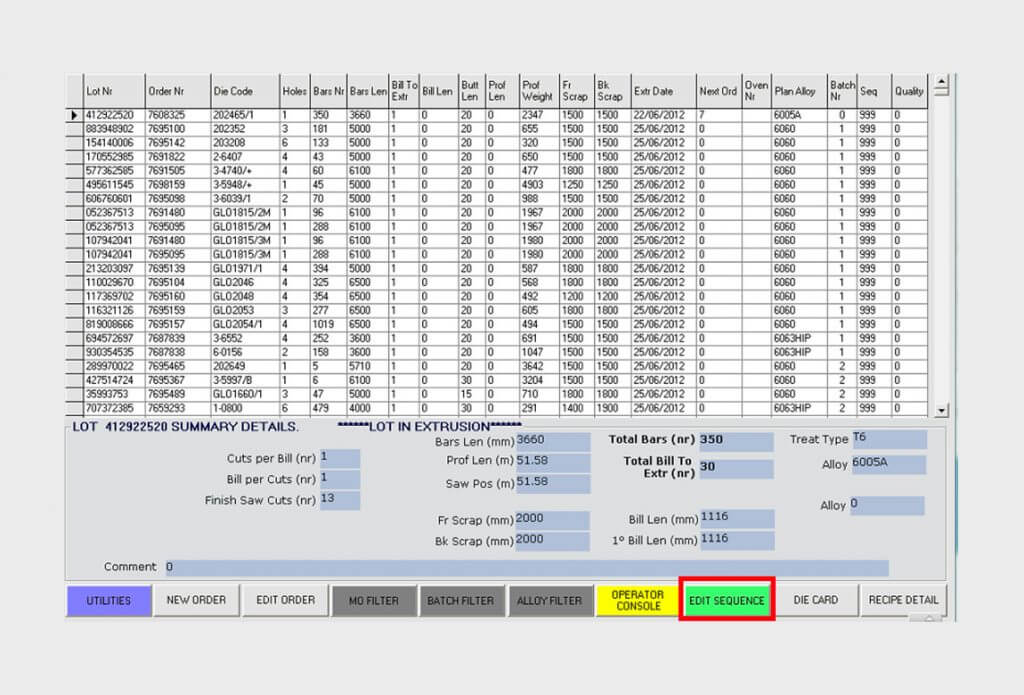

DETAILED PROCESS AND PRODUCTION

Reports enable engineering and management to make informed decisions about process improvements.