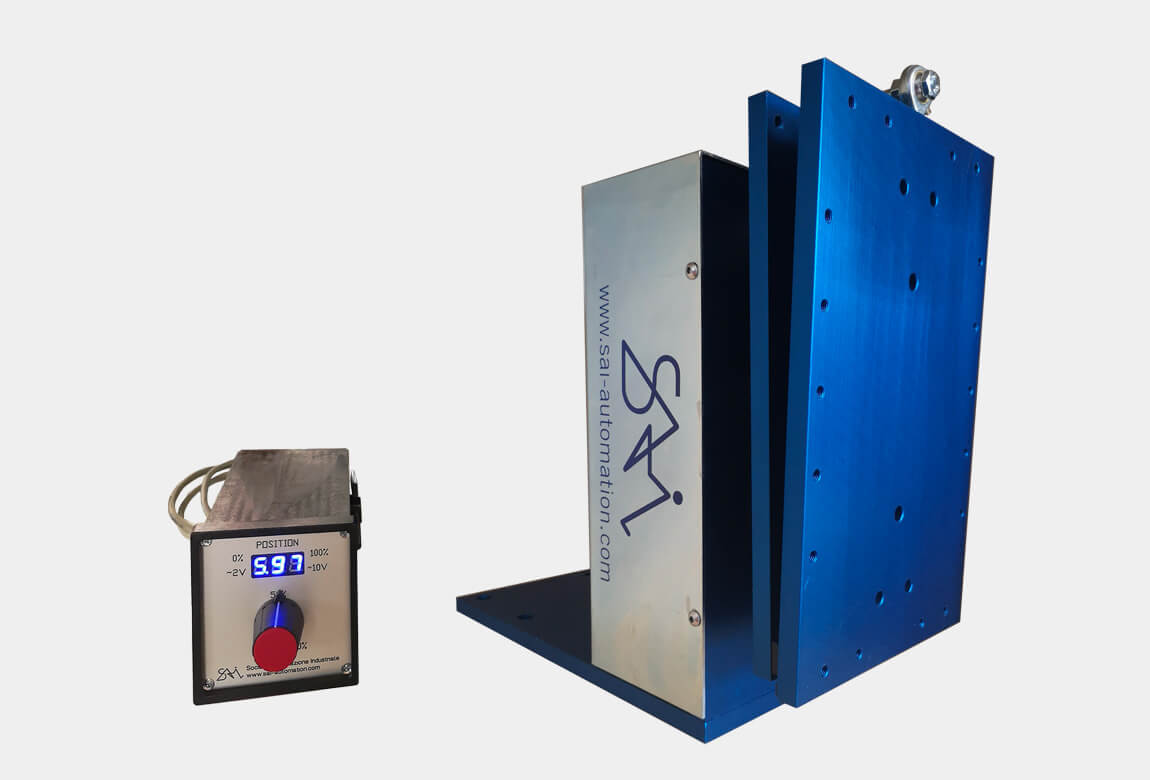

SCANNER

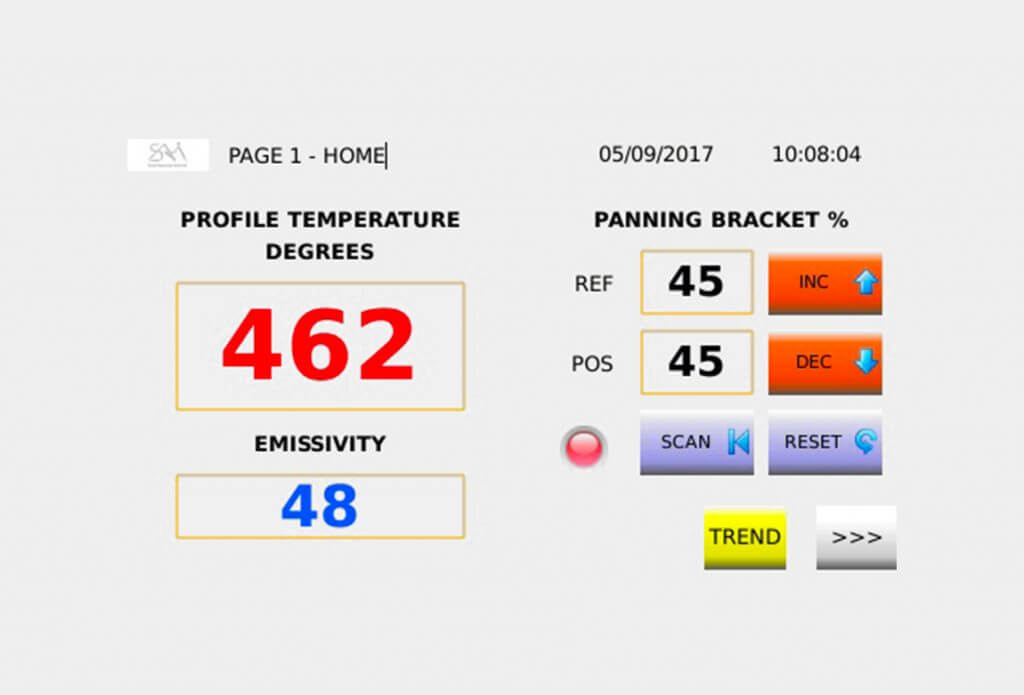

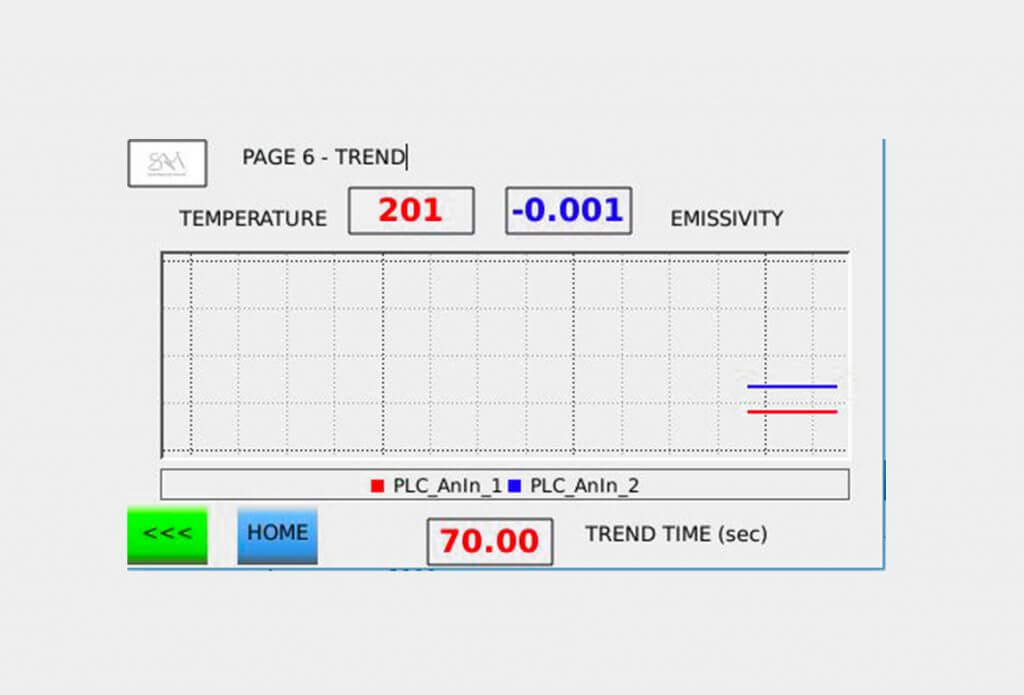

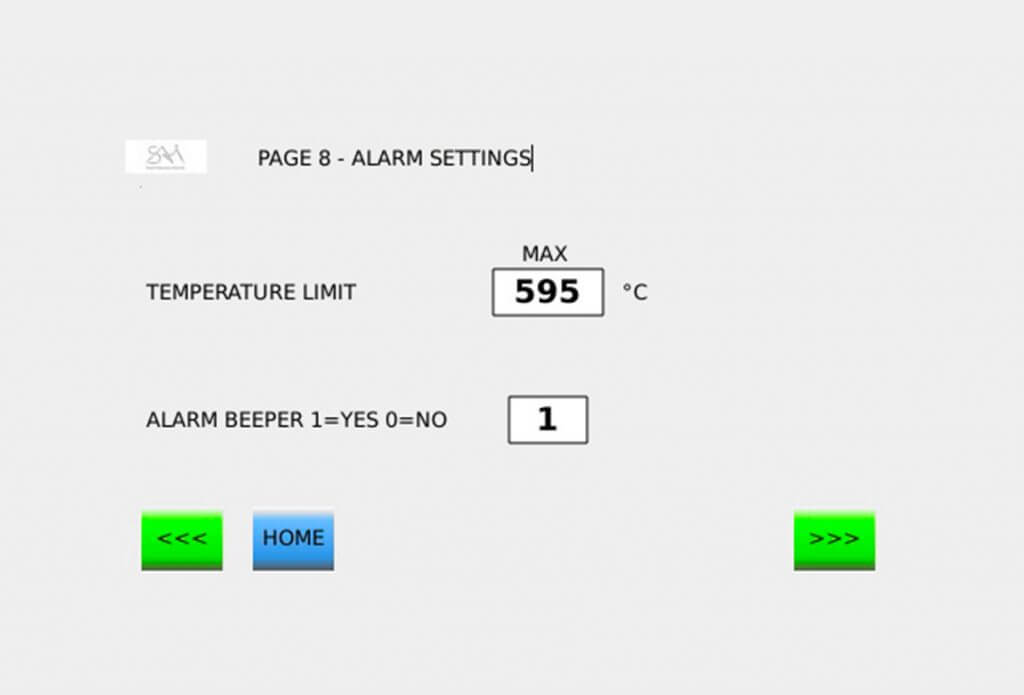

A reliable reading of profile temperature is important for the control of the extrusion process. For dies already in use, at die change, scanner moves sensor automatically to the saved position during the last extrusion of that specific die, using the parameters stored in the recipes. With a new die, the scanner moves to 45 degrees and evaluates the temperature and emissivity. If the signal is not within the accepted range by the system, or if for any reason the signal is interrupted, the scanner will automatically begin searching for a new location that meets the necessary requirements (temperature and emissivity). At the end of extrusion the position value is saved, with all other parameters, in die recipe and is available for next extrusion with the same die.